Genesis Blog>

What are the Key Benefits of using a CNC Laser ?

|21 June 2023.

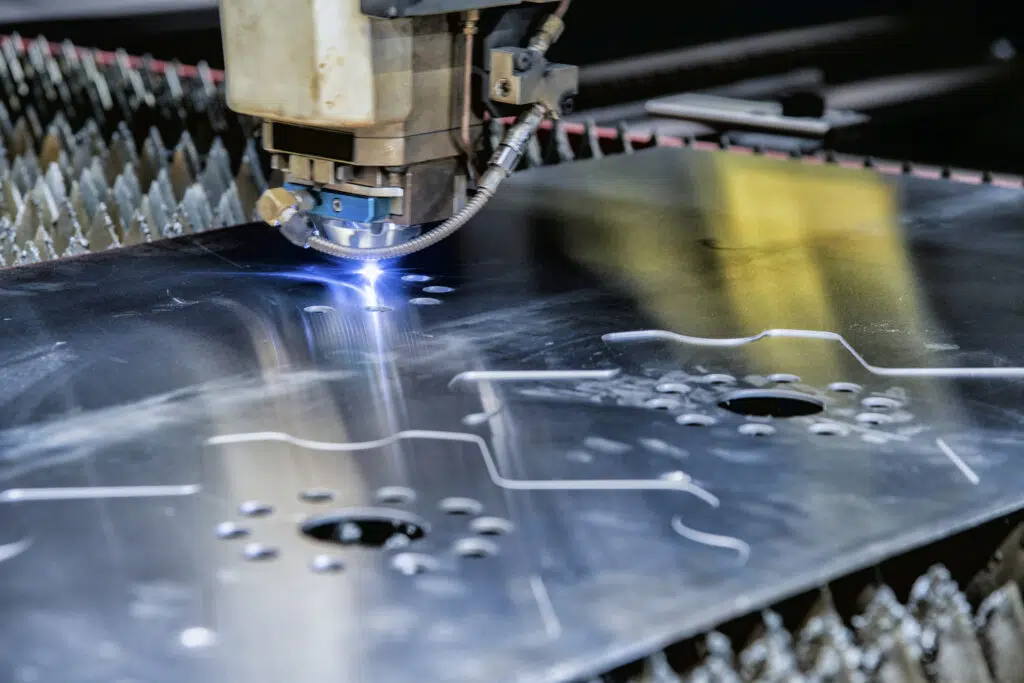

What are the key benefits of using a CNC Laser to Cut Steel?

- Precision and Accuracy: CNC lasers provide exceptional precision and accuracy in cutting steel. They can create intricate designs and complex shapes with tight tolerances, ensuring a high level of detail and consistency.

- Versatility: CNC lasers can cut various types and thicknesses of steel, including mild steel, stainless steel, and even hard steel. This versatility allows for multiple applications, from industrial components to artistic creations.

- Speed and Efficiency: Laser cutting with a CNC machine is a fast and efficient process. The lasers can cut through steel quickly, reducing production time and increasing productivity. Additionally, the CNC system enables automation and batch processing, further enhancing efficiency

- Clean and Burr-Free Cuts: Laser cutting produces clean and precise cuts without the need for additional finishing processes. The high-energy laser beam melts and vaporizes the material, resulting in smooth edges and minimal burrs. This saves time and effort in post-processing operations.

- Non-Contact Process: Laser cutting is a non-contact process, meaning that the laser beam does not physically touch the steel surface. This eliminates the risk of tool wear or damage, reducing maintenance costs and ensuring consistent cutting quality over time.

- Minimal Material Wastage: The narrow laser beam allows for precise kerf widths (the width of material removed during cutting), resulting in minimal material wastage. This efficiency is especially important when working with expensive or scarce materials.

- Design Flexibility: CNC lasers offer design flexibility as they can cut intricate shapes and patterns with ease. The software-controlled machine can execute complex designs accurately, allowing for customization and personalization in steel cutting projects.

- Reduced Contamination and Heat Affected Zone (HAZ): Laser cutting produces a small heat-affected zone (HAZ) compared to other cutting methods. This reduces the risk of distortion, warping, or changes in material properties. Additionally, the non-contact process minimizes the introduction of contaminants to the steel surface.

- Cost-Effective for Small to Medium Batch Production: CNC laser cutting is cost-effective for small to medium batch production runs. The setup time is relatively quick, and the process is easily programmable. This makes it suitable for both prototyping and mass production, without the need for expensive tooling or molds.

Note: It’s important to note that the specific benefits may vary depending on the CNC laser machine’s capabilities, the steel type and thickness, and the desired application.

Let’s Get Started

Let us know how we can help keep your equipment and facilities safe and your business working.